From simple to complex gear designs, we keep your products moving.

Everything under control

- every detail is important to us

Gear technology is our specialty! We back this up with decades of experience, and a tremendous depth of in-house manufacturing capabilities. This lets us control all quality-related parameters directly and perform complex machining tasks according to each customer’s needs, while maintaining the highest possible standards of quality.

Operations like turning, notch and gear broaching, worm and worm gear milling, gear shaping, gear hobbing as well as profile grinding, generation grinding, internal grinding, and circular grinding are among our core competencies.

Our facilities’ capacity and mixture of manual processes ensure your low- to high-volume orders will arrive on-spec, on-time, every time.

Don’t see the solution you need for your complex gear in our portfolio? We will design a new one.

Have a gear or splined shaft, but no documentation or standard defining its geometry or gear data? We can reverse engineer your sample to determine its specifications then reproduce it.

Want to make your existing design better? Our engineering expertise will provide you with the precision that cuts downtime. Reduces scrap. And saves your operation money. It’s easy to start.

Here are Gear Works capabilities that will help you stand out in your markets:

AVIRAT Gears

A process under control

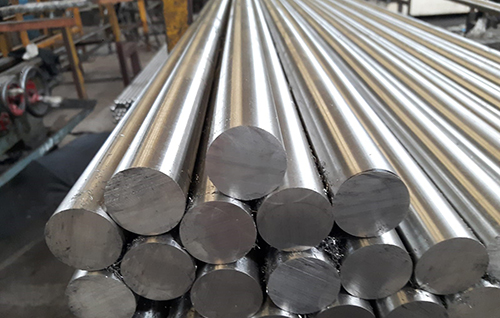

1. Raw material

AVIRAT Gears only use materials from leading international manufacturers that meet all the characteristics and requirements for the application of each component and the conditions in which it is to operate. Always checking/cross-verified the chemical compositions of received raw material from vendors with the use of Spectro and PMI Testing Instruments.

AVIRAT Gear’s is using raw materials by the different process:

Casting, Forging and Bars Stocks

Manufacturing Casting:

We are happy to introduce a joint venture with as manufacturer of Casting by Investment Casting, Green Sand, CO2 & Shell Mould With our well-equipped manufacturing plant. We specialized in manufacturing all types of Ferrous Casting, according to customer’s requirements. We manufacture castings EN, ASTM, IS standards or any international specifications in Stainless Steel, Cast Iron, Gray Iron, and Ductile Iron. As specified by the customers. Our product range includes the casting of the Valve Sector, Pump Sector, Automobile Sector, Food processing and packaging Machinery Industry, Agriculture Industry, Mining Machinery Industry, Railway, Defense, and General Engineering. Our single piece weight capacity is few grams to 1000kgs.

Manufacturing Forging:

Full Range of Forging by Closed Die and Ring Rolling

Forging, Turning, Milling and Drilling

Tooth Cutting, Shaving and OD & ID Grinding

Best Practices.

Pneumatic Hammer up to 6.5 tons

Mechanical Press 50 tons

We are amongst the most advanced gear production facilities. We are world standard, state of the art and forward looking organization.

We have always focused on the quality of products manufactured by AVIRAT Gears. We strictly implement Quality standards and our experienced engineers, machinery and precision quality checks for our products makes us the leading manufactures of the forging in the industry.

We at AVIRAT Gears also offer our clients a number of custom shapes and forges, even in complicated and complex forms for all forging need. Our high quality and strong forges can take care of your forging requirements, whether it's for research and development or specialized machinery. With our expert engineering teams, we further push the boundaries of creativity and innovation with precision in our industry.

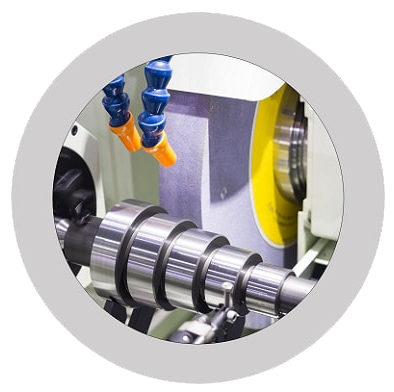

2. Turning

At AVIRAT Gears, for products that require a cylindrical form and a polished finish, we use the process of turning with our cutting edge CNC horizontal universal turning center. Turning is a machining process in which a straight edge cutting tool is parallel to the workpiece and makes linear cuts while the piece rotates, removing material from the workpiece, creating a final product that is cylindrical and evenly smooth.

The turning processes can be one of four different types such as straight turning, taper turning, profiling, or external grooving. These types of turning processes can produce various shapes of materials such as straight, conical, curved, or grooved workpieces. AVIRAT Gears uses the turning process for tight tolerance and cylindrical products.

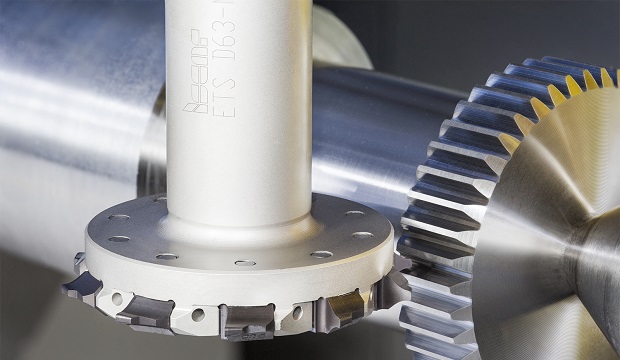

3. Hobbing

At AVIRAT Gears, for products that require a tooth form configuration, we use our state-of-the-art hobbing machines. Hobbing uses a gear hobbing machine with two skew spindles, one mounted with a blank workpiece and the other with the hob. When using a hob, the shape of the tooth is created by the combined motions of the workpiece and cutting tool.

The angle between the hob's spindle (axis) and the work piece's spindle varies, depending on the type of product being produced. Due to the shape of the hob, several cutting edges will be working simultaneously, which provides the potential for fast cutting speeds and/or short cycle times, which leads to fast production.

TGear hobbing is one of our specialties, for cutting splines, gears, and timing belt pulleys. With our high-end CNC Hobbers.

AVIRAT Gears uses coolant only for the hob, which achieves better chip breaks and longer tool life for high-speed cutting. Compared to other gear cutting techniques, hobbing is rather inexpensive, yet extremely accurate. At AVIRAT Gears it is our priority to provide the best quality product for our customers.

4. Milling:

At AVIRAT Gears Manufacturing, milling is one of our services that allows a product to be cut and formed into a precise shape and size with complete accuracy. Milling is the machining process of using rotary cutters to carve material from a work piece. It has the ability to cover a wide variety of different operations and products for any projects, on scales from small individual parts, to large heavy-duty items.

AVIRAT Gears uses CNC milling machines that include vertical and right-angle heads which minimize costly setup and results in faster machining. We offer machining, providing milling, drilling, pocketing, profiling, and facing. These precision machining processes can be applied to a variety of materials such as alloy and carbon steels, aluminum, stainless steel, and Non Ferrous materials. Our CNC Milling machines perform simple to intense milling operations with extreme accuracy and consistency, holding tolerances as close as 0.0001”.

5. Broaching & Gear Shaping:

Broaching is used for precision machining to produce products with unique shapes. Commonly broached surfaces include circular and non-circular holes, keyways, and straight sided, involute and external splines. At AVIRAT Gears Manufacturing, vertical broaching, shaper cutting and key seating are the services used to cut straight-sided and involute internal shapes, keyways and forms.

Keyseating is a machining process in which internal shapes and forms are cut using a single-point cutting tool. Similar to key seating, shaper cutting also uses a single-point cutting tool. The difference between keyseating and shaper cutting would be that a keyseater enters through the bottom of the work piece and cuts by using the down stroke, pulling material away from it, only to produce a keyway. A vertical shaper cutter enters through the top of the part and cuts using the down stroke, by pushing material away from the piece to produce a desired internal or external straight sided design.

AVIRAT Gears offers a variety of broaching services in many different sizes and styles that are sure to suit any broaching need. Our CNC shaper cutters and CNC vertical broaching machines are typically used for larger production cycles, offering versatility in size and irregular shapes, while maintaining accuracy, repetitive size control and quick production rates. For shorter runs, AVIRAT Gears provides high quality keyseating services that are primarily used to cut internal keyways and straight edged shapes.

6. OD ID Grinding:

At AVIRAT Gears, grinding is one of our services that allows for precision products that require surface tolerances to be ground with speed, accuracy, and an exceptionally smooth finish. Cylindrical grinding is the process used when making products with high precision and tight tolerances.

Cylindrical grinding is used to remove material from surfaces and shoulders of the workpiece and shows the advantage of high repeatability on tolerances and defined flank forms with closed loop corrections. OD grinding is the use of a grinding machine occurring on the external surface of an object, opposed to ID grinding which is used on the internal surface of the object. With the workpiece being spun on its axis, the grinding wheel is also being rotated as it comes in contact with the part. This effectively means the two surfaces will be moving opposite directions when in contact, allowing for products that have intricate detail and require extreme accuracy to be produced with a smooth and even finish.

AVIRAT Gears offers both OD and ID cylindrical grinding services that can assure a fine, quality finish on applications that require high precision shaping. Cylindrical grinding also reduces surface stress raisers and reduces fatigue cracking, extending the product life. Our grinding wheel can be shaped straight, or tapered to produce simple cylindrical shapes or it can be dressed in a complex shape to produce intricate contours on the workpiece.

7. Machining:

At AVIRAT Gear, we take pride in our ability to provide our customers with exceptional CNC turning and CNC milling services.

We can customize machining of components as per your specifications in round bars, square bars, Castings parts, and forging parts. Simply provide your blueprints, CAD drawings or worn out samples to our team. We will engineer and manufacture replacements of the highest quality, competitively priced.

We can also provide conventional turning and milling, grinding and cylindrical grinding as well as honing services. Honing of holes can be done to your required specifications and tolerances.

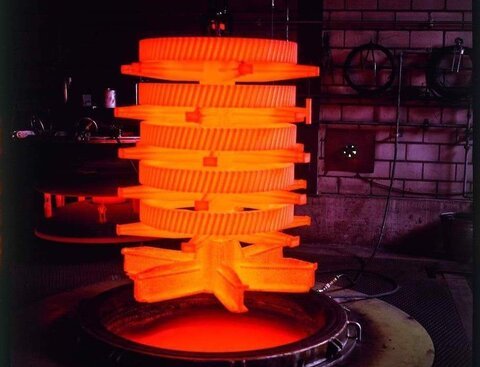

8. Heat Treatment :

AVIRAT Gears has broad experience in providing a range of heat treatment for its Gear and Machining Components. This is a vital point in ensuring their hardness, strength, and other properties.

We use the following processes:

Case hardening

Nitriding/oxidizing

Nitrocarburizing

Quenching and tempering

Annealing

9. Checking & Quality Assurance :

AVIRAT Gears whole production system operates on the basis of stringent quality control methods, to ensure that every gear manufactured meets the strictest requirements as regards precision and quality.

Always check the dimension and provide report for the same and also provide test certificate & testing reports to the customers. Check the Chemical properties and Mechanical properties and keep the records for the provided best quality in terms of best gear manufacturers.

10. Surface Treatment:

Gear surface treatment is to improve the surface state, generally have blackening treatment (surface oxidation) solid lubrication treatment, zinc, phosphating treatment, electro less nickel plating and RAYDENT surface treatment

11. Shipping :

AVIRAT Gears designs and manufactures its own packaging for transporting gears. This adds flexibility and security in the delivery of all our orders.

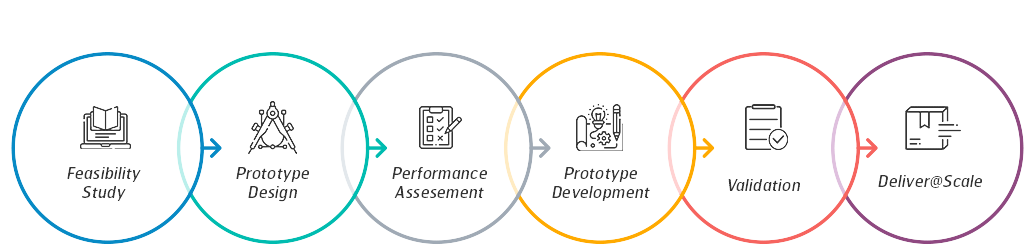

Product Development Capability

We have continually invested in innovation and technology which has helped us expand our production capacities. Today, our state-of-the-art facilities have the capability to manufacture customized products as per the requirement of our customers.

A leader in on-time delivery

Missed delivery dates are one of the biggest frustrations in your business. If the gears, spline shafts and components aren’t on your dock when you need them, you deal with costly production downtime. That’s why AVIRAT Gears Works sets the bar high for on-time delivery in our industry. We’ve invested in the Theory of Constraints model of lean manufacturing to ensure your orders arrive when you expect them. And if you face unanticipated production needs, call us. We are small enough to be agile, yet have the capacity to respond quickly so your lines keep running.